Vapour Permeable Membranes and Fire Safety in the Construction of Tall Buildings within the UK

In the realm of modern construction, especially for tall buildings, the balance between energy efficiency, moisture management, and fire safety is paramount. The recent advancements in vapour-permeable membranes have significantly impacted the construction industry, enhancing the performance, durability and fire safety of building facades. Among the leading products in this category are the illbruck UK façade membranes which have gained recognition for their superior qualities. This article delves into the importance of vapour-permeable membranes, their role in fire safety, and the specific attributes offered by illbruck façade membranes.

Understanding Vapour Permeable Membranes:

Vapour permeable membranes, also known as breather membranes, are essential components in building envelope construction. These membranes allow moisture vapour to pass through them while preventing liquid water from penetrating. This dual functionality ensures that buildings remain dry and free from condensation-related issues, thereby enhancing the longevity of the structure and improving indoor air quality.

Importance of Tall Buildings:

Tall buildings, due to their height and exposure to varying weather conditions, require robust moisture management systems. The use of vapour-permeable membranes in such structures is crucial for several reasons:

Condensation Control: In tall buildings, the temperature differential between the interior and exterior can lead to condensation. Vapour permeable membranes help manage this by allowing moisture to escape.

Energy Efficiency: By preventing moisture ingress, and in some cases being airtight, these membranes contribute to the thermal efficiency of the building, reducing energy consumption for heating and cooling.

Structural Integrity: Moisture can weaken building materials over time. Vapour permeable membranes protect the structural elements from moisture-related damage.

Fire Safety Considerations:

Fire safety is a critical aspect of building design particularly for tall buildings where evacuation can be more challenging. The Grenfell Tower tragedy in 2017 underscored the importance of fire-resistant materials in construction. Vapour permeable membranes must now adhere to stringent standards to ensure they do not exacerbate fire risks. In the UK, building regulations require that materials used in the construction of tall buildings meet specific fire standards. For vapour permeable membranes, this includes:

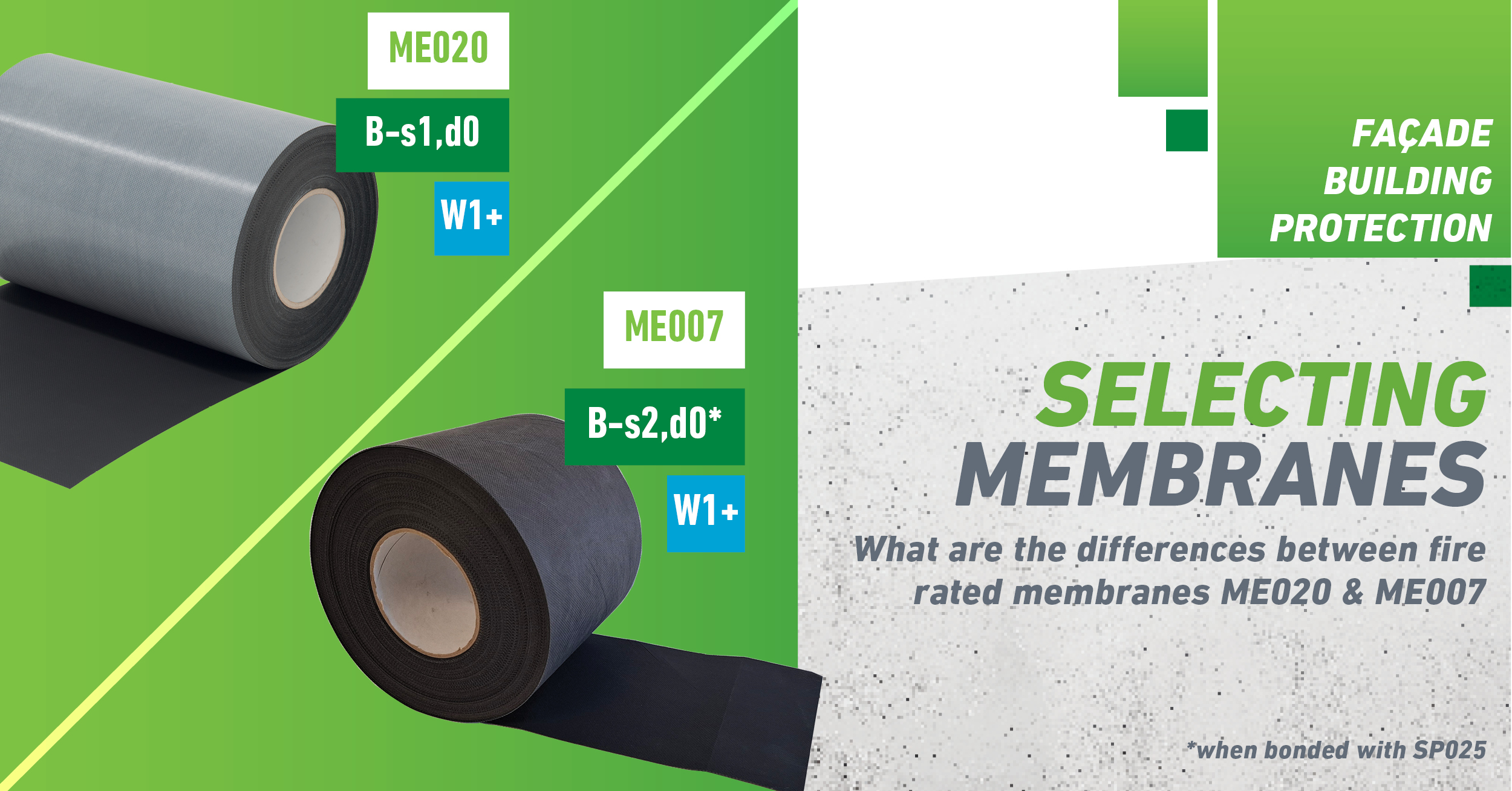

Reaction to Fire Classification: Membranes must achieve a minimum classification of Class B-s3, d0 according to the European standard EN 13501-1. This classification indicates that the membranes have limited contribution to fire and produce no significant smoke or flaming droplets.

Fire Resistance: In contributing to the fire resistance of the façade, membranes should be tested for reaction to fire to ensure they do not compromise the overall fire performance of the building envelope.

Illbruck, a prominent brand in the construction industry, offers a range of façade membranes that are designed to meet the highest performance standards, including fire safety. The illbruck façade membranes are known for their exceptional qualities, making them the perfect product for use within tall buildings.

Key features of the Illbruck façade membranes:

High Vapour Permeability: Illbruck’s membranes allow moisture vapour to escape from the building envelope, preventing condensation and ensuring a dry and healthy internal environment.

Water Resistance: These membranes provide excellent resistance to water ingress, protecting the building structure from moisture damage.

UV Stability: Illbruck membranes are meticulously designed to be able to withstand prolonged exposure to UV radiation without degrading, ensuring long-term performance.

Fire Performance: Illbruck façade membranes meet the required fire safety standards, including EN 13501-1 classification. They are engineered to minimise the risk of fire spread and do not contribute significantly to smoke production or flaming droplets.

Popular Products:

ME055 FR Breather Membrane (White) is a non-combustible and highly vapour permeable breather membrane which is A1 in accordance with EN 13501-1 and water resistant to Class W2 in accordance with EN 13859-2.

Ensuring compliance with Approved Document B, when used as a full façade breather membrane on new or refurbishment projects, this product is highly breathable and offers UV resistance for up to three months.